Electrify your service fleet without interrupting your schedule

Bring your own vehicle

We support a wide range of commercial fleet vehicles, from 1-tonne minivans to up to 9-tonne trucks.

We remove the ICE engine and drivetrain

Engine, gearbox and fuel systems are stripped out by our trained technicians.

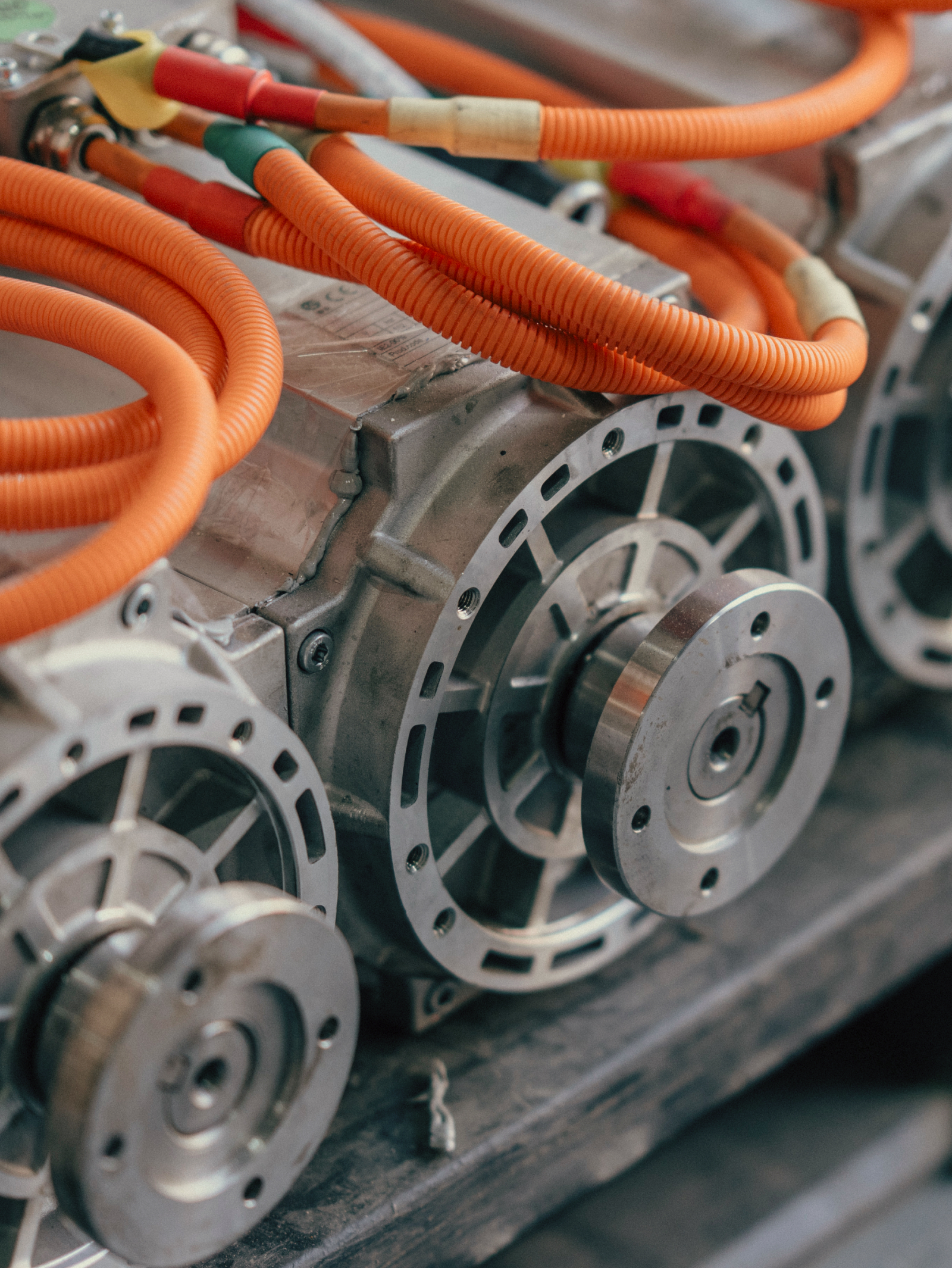

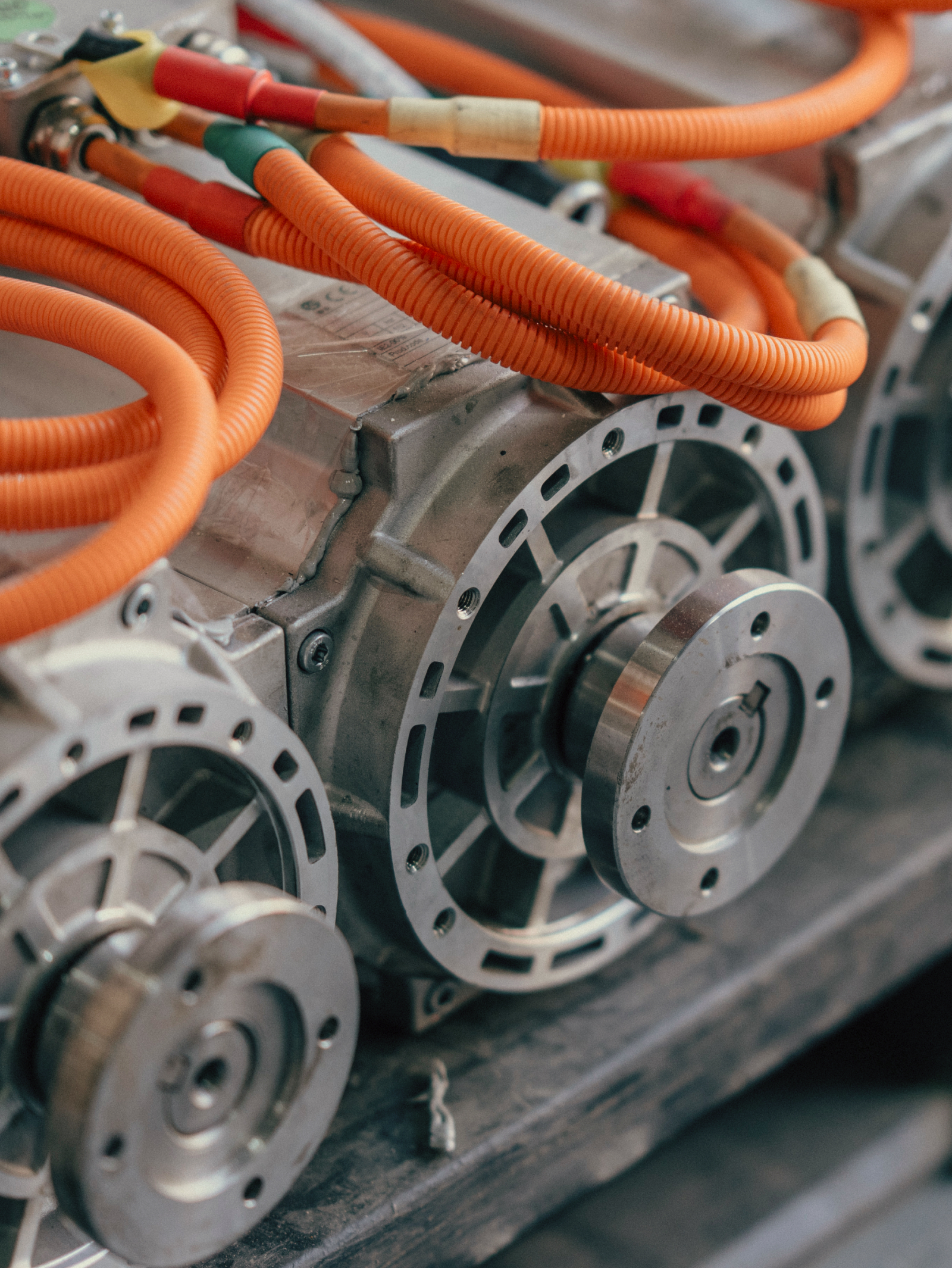

We install a new electric system

A modular EV drivetrain and battery pack are fitted — designed to slot into your existing chassis.

Stay connected with ShiftWare

Your vehicle is integrated with depot charging and fleet management software, included as standard.

Start driving and saving

No CapEx. No downtime. Just lower running costs and zero emissions.

Bring your own vehicle

We support a wide range of commercial fleet vehicles, from 1-tonne minivans to up to 9-tonne trucks.

We remove the ICE engine and drivetrain

Engine, gearbox and fuel systems are stripped out by our trained technicians.

We install a new electric system

A modular EV drivetrain and battery pack are fitted — designed to slot into your existing chassis.

Stay connected with ShiftWare

Your vehicle is integrated with depot charging and fleet management software, included as standard.

Start driving and saving

No CapEx. No downtime. Just lower running costs and zero emissions.

Electrify your fleet faster, cheaper, and smarter without upfront costs

Pay nothing upfront

Convert in one hour

Save straight away

De-risk transition

Shift EV works with you to electrify the vehicles you already own

We electrofit:

We electrofit:

We electrofit:

We electrofit:

We electrofit:

We electrofit:

FAQs

Shift EV offers Transition-as-a-Service (TaaS) — fleets pay a fixed monthly subscription that comes from their reduced fuel and maintenance expenses. There’s no upfront cost, and savings begin on day one. Customers can bring their own vehicle to be Electrofitted, or lease an Electrofitted vehicle from us, both backed by buy-back guarantees and uptime SLAs.

On average, Shift EV customers reduce operating costs by ~60% compared to diesel fleets, while eliminating depreciation risk and downtime. It’s a better TCO profile than both new ICE and new EV options.

Electrofitting converts the vehicles you already own into fully electric — at industrial speed and scale. We remove the engine and fuel system and install a Shift-designed electric drivetrain and modular battery pack, integrating directly with your existing chassis and controls. Our plug-and-play platform covers most commercial classes, from 1-tonne vans to 9-tonne trucks, across leading OEMs such as Ford, Renault, Isuzu and Toyota. Each conversion takes around one hour on our production line, using pre-engineered kits that slot seamlessly into existing vehicles. The result: a road-ready, warranty-backed EV that performs like new — but at a fraction of the cost.

Range depends on vehicle class and use case — but every Shift EV is engineered for real-world fleet performance, not lab conditions. Our electric minivans average 200 km per charge (±20%), while pick-ups reach around 150 km under mixed urban loads. For heavier applications, modular battery packs can be scaled to extend range without compromising payload. Before conversion, our engineers analyse your routes, mileage and load profiles to deliver the optimal configuration — so your fleet’s capability matches, or exceeds, what you run today.

Shift EV vehicles integrate seamlessly with standard AC and DC infrastructure, including overnight depot chargers, on-route top-ups, and simple wall-mounted units. As part of every project, we assess your fleet’s duty cycle and design a charging setup around your operations — from private depot installations to shared hubs. All systems connect directly to ShiftWare for live visibility on charge status, energy costs, and usage trends.

Reliability is built into every layer of our system — from engineering to after sales. Each vehicle is covered by a 99.9% uptime Service Level Agreement (SLA), meaning your fleet stays on the road and earning. Our modular drivetrain design simplifies servicing: components are pre-engineered for rapid swap-outs, not lengthy repairs. Maintenance is planned, predictable, and handled through a nationwide partner network trained on Shift EV systems. Through ShiftWare, you’ll receive proactive alerts for battery health, component wear, and service intervals — enabling maintenance before downtime occurs. The result: fewer breakdowns, lower operating costs, and total visibility on fleet performance, day and night.

Each converted van eliminates the equivalent emissions of 10 ICE vehicles per year, avoiding ~5.25 kilotons of CO₂across 1,000 vans. And because the vehicle’s “carbon debt” has already been paid during its original manufacture, Electrofitting produces 40% less carbon than building a new EV.